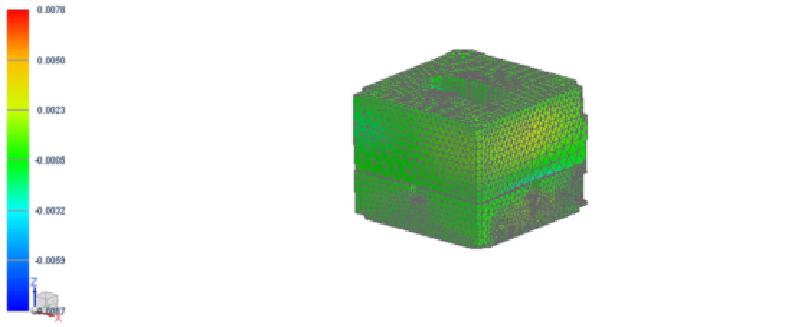

Breakthrough in die CAE Technology

Most of the work in automobile, construction, shipbuilding, aerospace and other fields adopts computer-aided technology. Moldflow is mainly used in the mold industry for product filling, pressure holding, warping and cooling analysis. However, CAE analysis technology in the direction of die strength and stiffness has not been widely used. The current situation is that large molds only rely on individual experienced designers to design molds according to experience. There is no guiding data in ensuring strength analysis and verification and mold design results. Wrong design and over design often occur.

Combined with NX advanced simulation module, Huazhuo analyzes the strength, stiffness and fatigue durability of the mold structure, which is widely used in precision molds (bottom shell, panel, panel body and other products) and lamp molds (housing and other products). It ensures the mold quality, maintains the interests of the company and meets the needs of customers at the same time.

Good quality benefits from our company's continuous breakthrough and innovation in technology!

Significant effects:

1. Convert mold empirical data analysis into data quantitative analysis.

2. The physical parameter library of different materials ensures that the analysis results are more reliable.

3. Avoid excessive design section and save material cost.

4. Avoid weak design, analyze and prevent in advance to ensure quality. |